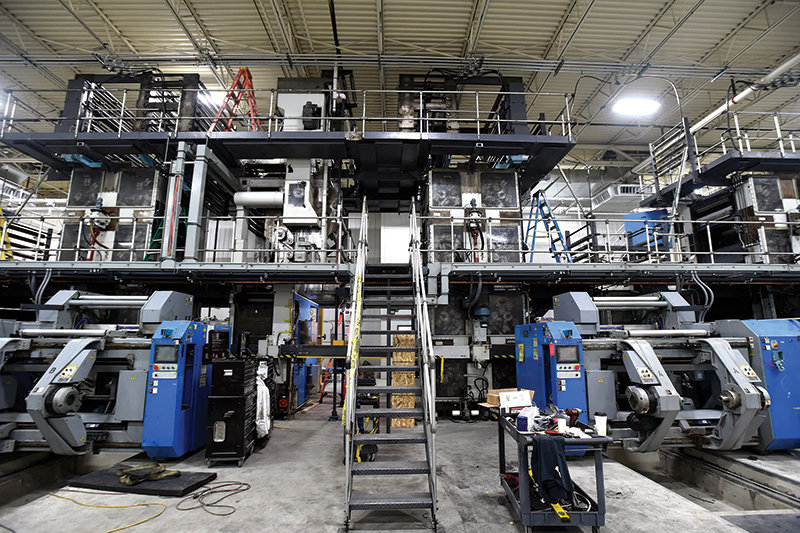

Workers installed the new printing press for LNP Media Group in June. (Photo by Chris Knight)

Workers installed the new printing press for LNP Media Group in June. (Photo by Chris Knight)

In August, I wrote an article for E&P referencing the lack of innovation in our industry. That article drew quite a bit of ire from many diehard printers. Most of the production folks that read a “production column” are printers, and most printers have had enough, hearing about the wonders of the digital world, consolidation, newspapers closing, job losses, the death spiral of print, etc. One individual even commented to me “It’s the same old rhetoric.”

In this day and age you really don’t hear a lot of good news from printers. But we’re all getting tired of hearing the woes of the industry and deserve a little positive news for once.

New equipment installations seem to be a thing of the past, and the investments that many of us made yesterday are now being cut up for scrap metal or sold to some offshore newspaper start-up. It seems we don’t have a lot to celebrate and the majority of us are settling into that “same old rhetoric” and accepting that newspapers are in big trouble and the vultures are circling.

The good news is that’s not the way they see it in Lancaster County, Pa. Matter of fact Steinman Communications, the parent company of LNP Media Group, firmly believes in the power of print and is bringing its operations back to Lancaster County with a vengeance.

I recently spoke with Robert M. Krasne, chief executive officer of Steinman Communications, about the decision they made to bring printing back in-house—a decision that shows their confidence in print, the strength of newspapers and makes a strong commitment to their community.

Krasne appeared before a crowd of business and community leaders as well as the governor of the Commonwealth of Pennsylvania at an event held to commemorate LNP’s 225th anniversary this past June. Krasne made several announcements that were significant to LNP and the community; however, the one that generated the most buzz was the return of printing to Lancaster County.

Let’s go back four years to 2015 and retrace the path that brought LNP to this milestone decision. I asked Krasne why Steinman Communications shifted production from downtown Lancaster to an outside printer in the first place.

He said, “LNP was printed on a manroland Flexoman that was no longer supported by the manufacturer. Many of the supplies could only be obtained from single sources and some were overseas, which created significant additional transportation costs. It was not financially or practically sustainable. We considered expanding our sister operation in Ephrata (a borough in Lancaster County), constructing a new facility, or outsourcing and determined that the most cost-effective path was to outsource.”

From my personal perspective, I can certainly understand this business decision. Many of us with presses manufactured outside of this country have at times experienced challenges acquiring parts, and there have been times I’ve had to wait several weeks for a part to be manufactured and shipped from abroad.

In 2015, when Steinman decided to outsource printing of LNP, the switch cost them about an hour of news coverage on the front-end. Their new printer was located in Mechanicsburg, Pa., adding transportation time and creating challenges on the news side for late-breaking stories and coverage of significant evening sports events. LNP now expects to recover all of the “lost time” by moving printing back in-house to Lancaster County.

Discussing that lost time with Krasne, he said, “Today our distribution team prides itself on getting LNP ‘on the porch’ before 6 a.m. daily. We receive relatively few complaints about delivery and we intend to continue that standard. We reverse engineered schedules to ensure that we could maintain our delivery commitment when we moved printing to Mechanicsburg.”

I asked Krasne what the reader reaction was to moving printing out of the community in 2015. Obviously Steinman put quite a bit of thought into the move, as well as meeting with community leaders and explaining the business reasons for the change. They were candid with readers, honest and transparent with their community and subscribers alike. Krasne admitted “neither they nor we were happy about it, but everyone understood the business imperative.”

Prior to 2015, LNP was printed and packaged in a facility in the heart of downtown Lancaster. Steinman recently contracted to sell that site to a developer who operates a significant 55+ community in the area. They plan to construct a residential tower on the site that will be transformational for the city of Lancaster.

Krasne said that because of their efforts to help the community understand the logic behind the 2015 decision on the front-end, they did not receive many complaints when a late-breaking story or sports score didn’t make presstime.

So, let’s move to present time and talk about bringing production operations back to Lancaster County.

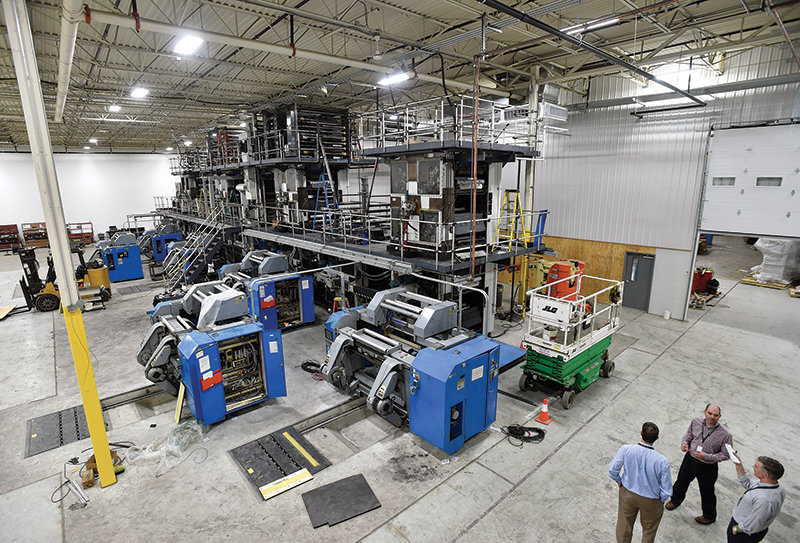

The current press installation boasts 10 units of Goss Universal 70, consisting of 36 printing couples; four 4/4 color towers and two mono units. The press has a 48 broadsheet page capacity with 32 of those capable of being produced in full color. Of course with the anticipation of new commercial work, it’s important to note that the ability to produce tabs and booklets is also strong—with a 96 page tab max, 64 of those pages in color; and 192 page booklets with 128 in color. This is certainly quite a bit of press.

As far as speed, with a manufacturer rated speed of 70,000 impressions per hour; many runs that took all day for LNP will now be done locally in a much shorter timeframe, allowing additional open windows to gain outside printing.

In addition, “The operation in the 48,000-square foot leased building…will eventually be run by 30 to 40 employees, including the 12 positions that are being transferred from Ephrata,” according to a LNP article.

Ralph Martin, executive vice president of Steinman Communications, said in the article, “There’s just a lot of ‘new,’ and were anxious to get things started so we can see how the ‘new’ is working.”

Below is my Q&A discussion with Krasne. It should be obvious to anyone reading this article that Steinman Communications is serious about journalism and a proponent of not only all media but also about the community they serve. Today, in the face of corporate consolidations and the elimination of print sites and catastrophic job losses in the media, companies like Steinman and LNP Media Group should hold their heads high and be proud to put their money—and their ink—where their heart is—print.

E&P: Could you describe a bit more what “a fully automated system on press” constitutes?

Krasne: In addition to the automated control of the press, the system controls water, ink, image and registration, as well as systematic control of newsprint waste.

What was the approximate financial investment LNP made to bring printing back in-house?

Significantly less than what we estimated the cost of creating a new facility was when we made the decision to outsource production of LNP five years ago.

As a result of the press installation, did you make any changes in the mailroom and if so what are they?

A new mailroom was constructed to support the press speed and configuration in conjunction with the increased volumes from additional jobs flowing through the new mailroom. All conveyoring, stackers, online/offline inkjet system, two Mueller stitcher trimmers, and inserting equipment consisting of a 22 pocket Alphaliner with inkjet capabilities and a 22 pocket double-out full repair NP632.

What is the plan for shifting over from the outside printer in Mechanicsburg to your new Greenfield Corporate Center site in the East Lampeter Township?

We anticipate moving our products currently printed in our Ephrata facility to our new facility over the next few months. We will also be migrating our contract work from Ephrata to the new facility during this same period. We plan to move LNP directly from our outside printer all at once when the current contract expires.

With the move of Lancaster Farming, Ephrata Review, The Elizabethtown Advocate and The Lititz Record, how many jobs (if any) will be lost in the Ephrata Borough? Are these employees being offered a transfer?

We anticipate transferring all of our full-time press and mailroom personnel from Ephrata to the new facility. We will assess our needs for part-time personnel as the move occurs and we settle into our new facility.

An inside look at the new press (Photo by Chris Knight)

An inside look at the new press (Photo by Chris Knight)

How many new jobs were created in the Greenfield printing site?

We have created roughly half-a-dozen jobs in administration or the mailroom, based on the demands of our growing business.

Do you anticipate a learning curve for pressmen on the new press?

The pressmen have no learning curve on the press but are being trained on the fully automated control systems.

It’s very difficult in most of the country to find qualified press operators. How successful were you?

Between our talented staff and plant closures/significant changes in production scheduling in our region, and a robust local training program, we have not had problems finding qualified press operators.

What experiences over the past four years, or what general thoughts happened to create such a change, bringing production back to Lancaster?

The owners of Steinman Communications wanted to control the destiny of their printed products and believed the best way to do that was to control not just the creation of the products, but the production and distribution as well. Thanks to an intrepid team with sharp pencils, we were able to come up with a plan that would bring printing of LNP, Lancaster County’s daily newspaper, back to Lancaster County. Given the increased speed and capacity of the new press and mailroom, and the surprising strong demand for printing and mailroom services, we have been able to craft a business plan that ultimately saves money for LNP Media Group.

When a majority of newspapers in the country seem to be focusing on digital, why would you decide to put in a new press?

Your question suggests that we are not focusing on digital. That is not true. We have a robust digital subscription model that we rolled out less than 18 months ago and its acceptance has exceeded our expectations. Our client solutions teams are providing innovative and effective multi-channel marketing campaigns for businesses in Lancaster County and beyond. We have a video team that creates branded videos that help clients convey messages very effectively to vast audiences.

(Caroline Muraro, president of LNP Media Group, added: “We are doing all of this while, at the same time, creating meaningful, unique local journalism for audiences in Lancaster County and beyond. The journalism we create, and the customer messages we convey are delivered both in print and online. Our audiences demand both and because access to broadband is not pervasive, we want to be able to reach anyone who wants to have access to our journalism and other content.”)

I understand that flexibility comes into play. How do you define the flexibility you lost in 2015 and now look forward to gaining it once again?

Flexibility comes in many forms. I anticipate that we will gain nearly an hour before we need to go to press, giving us the ability to include late-breaking stories and sport scores in the paper the next morning. We will be able to change more easily in the middle of a press run. We will also be experimenting with the look and feel of parts of our papers, and how they are put together as we grow accustomed to our new press. When we operated the Flexoman, our pre-press and press people did amazing things. In fact, when senior leaders of manroland came to visit just prior to our shutdown, they could not believe what the team was able to produce on the press. I anticipate similar innovation on our new press.

With all this new press and mailroom capacity, how serious are you going to be about outside commercial printing?

We are very serious about getting outside commercial printing as well as outside mailroom and packaging work. We had a considerable amount of this work in Ephrata, and with the newer, faster, and more dynamic equipment we now have, we will be able to do more even better and faster than ever before.

Jerry Simpkins has more than 30 years of experience in printing and operations in the newspaper industry. Contact him on LinkedIn.com or at simpkins@tds.net.

Jerry Simpkins has more than 30 years of experience in printing and operations in the newspaper industry. Contact him on LinkedIn.com or at simpkins@tds.net.

Comments

No comments on this item Please log in to comment by clicking here