Newsprint warehouses that months ago were full now look quite different. Recent tariffs on uncoated groundwood papers from outside the U.S. have shortened supplies and driven up costs.

Newsprint warehouses that months ago were full now look quite different. Recent tariffs on uncoated groundwood papers from outside the U.S. have shortened supplies and driven up costs.

Ignorance is bliss, and I’m the frontrunner for king of the castle.

When I pull into a gas station to fill-up and fuel has jumped 20 cents a gallon overnight, I don’t ask questions. I simply consider the options: walk, Uber, beg a ride from a friend, buy a moped, or go home and crawl up in a ball. Then, I dig deeper into my wallet and turn a blind eye until the next increase at the pump shocks me deeper into denial.

Until recently, I couldn’t imagine that same ignorance would ever enter my work life. Then along came newsprint tariffs. I reasoned that newsprint prices have fluctuated constantly throughout my career and this latest increase was just another one of those things we couldn’t control, so we’ll take it in stride and move on to something we could control.

It was at this point I realized I was leading the pack for ultimate king and figured perhaps this “tariff thing” was something more than just another attempt by my local newsprint supplier to push up costs and line their pockets—it’s an action that could jeopardize more than 600,000 workers nationwide in the publishing and paper industries and significantly drive up costs for us all.

What are the Newsprint Tariffs All About?

According to a Buffalo News article posted on the STOPP (Stop Tariffs on Printers & Publishers) website, the current newsprint tariffs are driven by a strategy of North Pacific Paper Co. (NORPAC) to manipulate U.S. trade policy. Other articles on the STOPP website go on to explain that after the recent purchase of NORPAC by One Rock Capital Partners of New York, (who on their website describe NORPAC as “a carve-out from Weyerhaeuser and Nippon paper”), “NORPAC, an outlier in the paper industry that is looking to use the U.S. government for its own financial gain” filed a petition resulting in duties which were assessed by the Department of Commerce in January and March.

The primary duties assessed were countervailing duties (CVD) and anti-dumping duties (AD) on imports of Canadian uncoated groundwood papers including newsprint and other papers. I highly recommend you review the STOPP website at stopnewsprinttariffs.org for a detailed explanation of these terms.

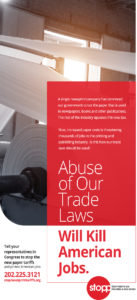

The News Media Alliance and the STOPP Coalition recently provided several ads for newspapers to run in their publications in order to educate readers on the negative consequences of the recent tariffs.

The News Media Alliance and the STOPP Coalition recently provided several ads for newspapers to run in their publications in order to educate readers on the negative consequences of the recent tariffs.

Before I get into the impact these tariffs will have on our industry, I want to give credit to STOPP for their efforts. STOPP recently launched its new website and is inviting any interested parties to join in the fight to overturn these tariffs which have the potential to be devastating to our entire industry.

Joel Quadracci, chairman, president and CEO of Quad Graphics, was quoted by STOPP saying, “This will result in driving up the costs of print and force an even faster migration to digital options at a time when our industry is already being severely disrupted.”

That about sums it up, but there is so much more that can be said.

One of the more recent articles I’ve read on newsprint tariffs was published by Paul Tash, chairman and CEO of Times Publishing Co. (publisher of the Tampa Bay Times). I felt it accurately reflected how the tariffs will hurt readers and the industry in general. Tash hits on many of the same subjects I’ll cover here, including his statement that “To help offset the extra expense of paper, publishers will eliminate jobs. Make no mistake: These tariffs will cause layoffs across American newspapers.”

Tash also states that “now that the tariffs are taking effect, the American companies are hiking their own prices, so we have little room to shop around.”

This “fallout,” as I choose to refer to it, is collateral damage from a trade war we didn’t really want to get into.

I recommend you get involved with STOPP. They are doing excellent work defending our industry against what some consider the most significant industry challenge to come along in awhile.

According to STOPP, the International Trade Commission is conducting its final investigation throughout the spring and is expected to reach a final determination regarding any injury or potential injury to the domestic industry by September of this year. Until then, we’ll all be paying as things work their way through Washington.

As an industry, with many of our brethren hanging on by slim margins and facing tariffs that could send them over the edge, the first thing we need to do is have a plan. While the cost/percentage of increase is still up in the air, rest assured it will have a significant impact on how your newspaper does business in the future.

With the steady decline of print media over the past years, most properties have already dipped into the “savings well” time and time again, and right now it’s just about dry. Things that we do to offset this tariff will most assuredly have a negative effect on the printing industry as a whole, and I sincerely hope that we can recover. Those of you who know me well have probably never once heard much “politics” come out of me (it’s not my style), but I wholeheartedly agree with a statement by The Daily Signal that “an America first policy is the one that supports the job-creating investment of a dynamic economy. Taxing newsprint is a backward-looking, America-last, investment-last, and jobs-last policy.”

Outside of labor costs, the most significant expense to newspapers is newsprint. Increases in groundwood papers as a result of tariffs on imported paper will result in additional expense to printers and force cutbacks in other areas of our operations.

Outside of labor costs, the most significant expense to newspapers is newsprint. Increases in groundwood papers as a result of tariffs on imported paper will result in additional expense to printers and force cutbacks in other areas of our operations.

Next Steps

So it’s time to get to the core of the issue—what can we do about it?

Sit down with your newsprint budget and make your best assessment of how much your budget is going to swell from these tariffs. In the aforementioned article by Tash, he estimated that the Tampa Bay Times could be facing more than a 30 percent increase, adding more than 3 million dollars in annual newsprint expenses. That is a staggering number and one that will not be able to be absorbed into normal operating expenses.

Let’s go after the less painful cuts first and slowly you’ll see a progression towards less desirable solutions. I want to be clear that I understand that most—if not all—of these may have already taken place in your newspaper. My suggestions are to simply review these ideas and implement them as they fit into your organization.

Before I wrap things up, I’d like to touch on price increases and supply shortages from U.S. newsprint suppliers. At least one of these suppliers—Resolute—has joined STOPP to fight the tariffs, and I applaud them for the effort.

When the tariffs were announced, almost instantaneously U.S. suppliers passed along an increase of their own. I spoke with a Resolute representative and asked why a U.S. supplier, located in the U.S., to whom we don’t pay an import fee to would increase their pricing. It truly seemed to me like kicking publishers while they were down. I don’t know if the answer justifies things, but it did make some sense to me.

U.S. mills are currently operating at 97 percent of capacity. Resolute alone has taken 70 machines off-line since 2007 in response to industry cutbacks. It isn’t easy, quick or inexpensive to get these mills back up and running, so for at least the immediate future, we’re going to have to deal with shortages and higher prices from U.S. suppliers due to the fact they’re working overtime and putting additional capital into their operations to keep up with supply and demand.

Regardless of NORPAC’s stand, it is apparent to me that this is not a trade matter, but more so a result of the steady decline in print products resulting in the progressive decline in demand for newsprint across the U.S.

So far, more than 1,100 newspapers had already written letters critical of the tariffs and warning that imposing retaliatory import duties would have a “very severe impact on our industry.” Evidently, these pleas fell on deaf ears in Washington.

Jerry Simpkins is vice president of the West Texas Printing Center, LLC in Lubbock, Texas. Contact him on LinkedIn.com or at simpkins@tds.net.

Jerry Simpkins is vice president of the West Texas Printing Center, LLC in Lubbock, Texas. Contact him on LinkedIn.com or at simpkins@tds.net.

Editor's Note: Senators recently introduced the "PRINT Act" to protect printers and publishers from unwarranted tariffs.

Comments

No comments on this item Please log in to comment by clicking here